Introduces some of the requirements and limitations of building the SUFST 2013/14 bodywork.

This series of articles document some of the work done during 2013/14 for the Southampton University Formula Student Team SUFST. As the Head of Aerodynamics & Bodywork it was my responsibility to lead the design and manufacture of the external surfaces. This involved using CAD and CFD software for design and simulation. Knowledge of composite structures was also required to manufacture the final parts.

Being only the second FS car desgined by the current team, knowledge, money, partners and University buy-in were all very limited! It was a case of 'finding a way' when it came to manufacturing the bodywork for this car. I'm not sure composite panels of this size could be made much cheaper. A lot of work did happen outside of core hours, hence the very professional workspace! Layup and the chemicals involved were also not permitted in our University garage at the time.

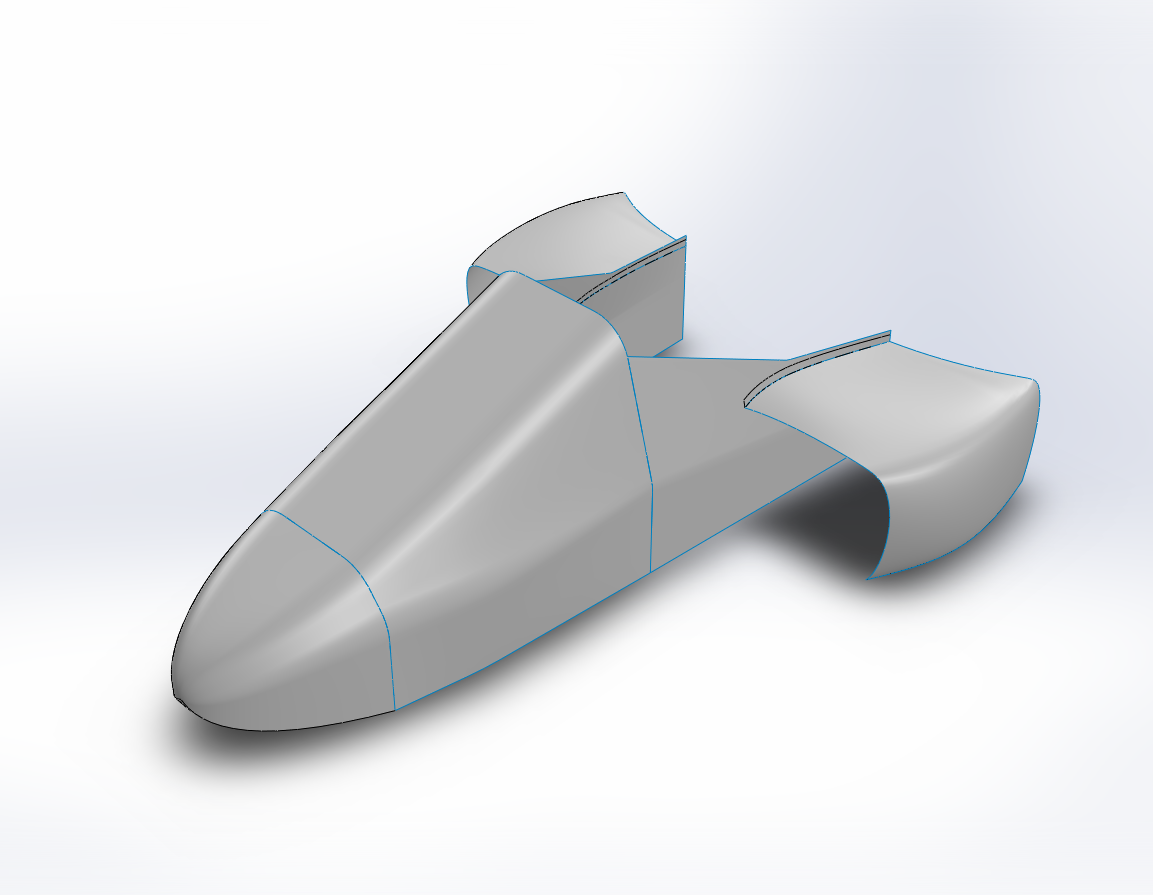

The car design looked like:

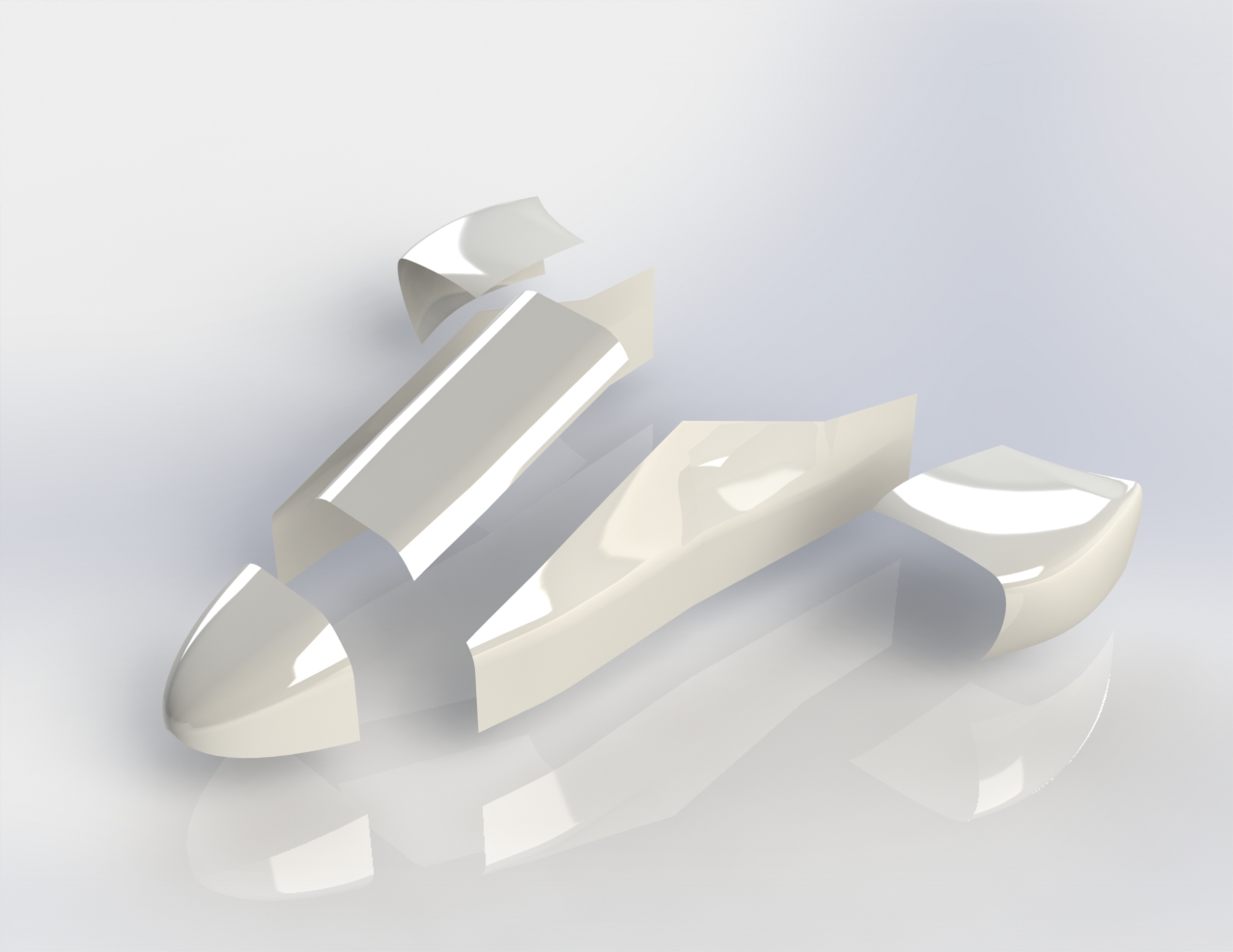

Initially the design included sweeping bodywork and an aerodynamic underfloor/diffuser. The underfloor was however dropped towards the final parts of the process due to time and money constraints. A flat panel would replace the profiled underfloor and provide support for the radiator shrouds. The parts (shown in an exploded view below) were designed to be easily demountable. The two sides would be permanently attached to the car and mounted before the suspension is attached. They have a curved lip and 'sit' on the flat floor. the rest of the panels then lock into the side panels for a flush fit.